Choosing the Right Countertop Contractor for Kitchen Remodeling Success

Outline and Why the Right Countertop Contractor Matters

Before diving into decisions, here is a quick outline of what you will learn:

– Section 1: Why the countertop specialist you hire determines fit, finish, and durability, plus a roadmap for the entire process.

– Section 2: Defining scope, budget, and material options with realistic ranges and maintenance needs.

– Section 3: How to find, interview, and vet a contractor with verifiable credentials.

– Section 4: Template-to-installation milestones, quality checks, and safety on site.

– Section 5: Sustainability, care, return on investment, and a final checklist you can use today.

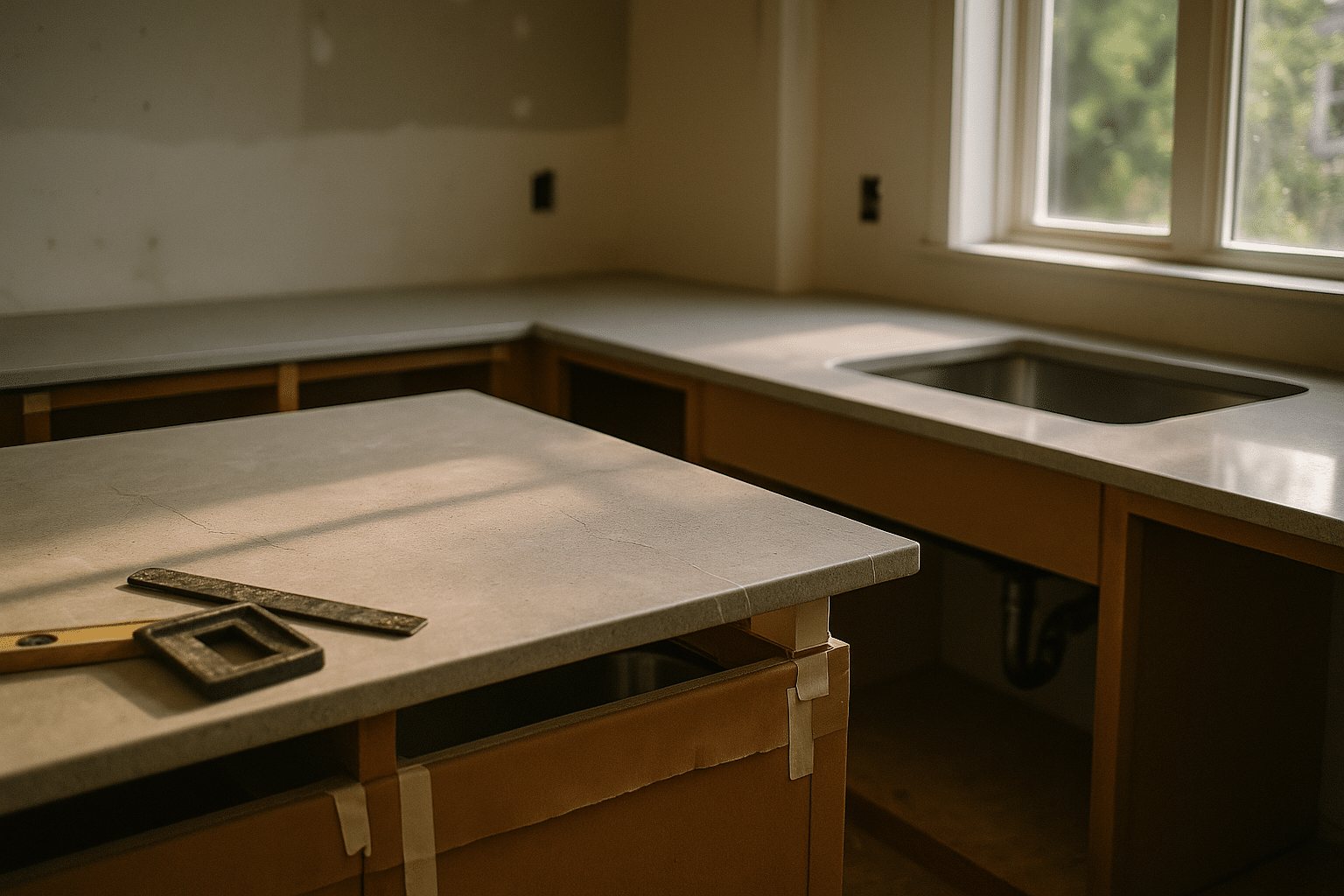

Countertops are more than showpieces; they are work surfaces that endure knives, pans, heat, and daily spills. That is why the specialist you choose can elevate or derail kitchen remodeling. A skilled contractor reads layouts like an engineer and a designer, managing tolerances at walls that are seldom square, aligning veining across seams, and calculating support for overhangs and appliance cutouts. Even small choices affect performance: seam placement near a cooktop can stress adhesive with thermal expansion, while underbuilt support on a peninsula invites deflection and hairline cracks over time.

The right professional also protects your schedule and wallet. Expect clear measurements, digital or rigid templates, and documented approvals before a slab is ever cut. Look for transparency about lead times (often 5–15 business days from templating to install), site prep requirements (plumbing and electrical shutoffs, cabinet readiness), and what happens if walls are out of true or slabs have natural fissures. A careful contractor will suggest practical enhancements, such as plywood sub-tops where needed, mitered edges for waterfall ends, or slight radius corners to reduce chip risk.

Finally, good project hygiene shows up in small, consistent habits: labeled templates, protected floors, taped sink templates for confirmation, and a written punch list. These steps reduce costly change orders and ensure both beauty and durability in your finished space. As you proceed, use this guide as a companion to ask informed questions, compare bids apples-to-apples, and set expectations that steer the job toward a calm, predictable finish.

Defining Scope, Budget, and Materials That Fit Your Vision

Clear planning reduces surprises. Start by mapping the work triangle and adjacent traffic paths, then list every cutout and accessory: sink style, faucet holes, cooktop dimensions, downdraft, air switch, soap dispenser, and any pop-up outlets. Note backsplashes, full-height accents, window returns, and the desired edge profile. Upfront clarity is the quiet engine that keeps kitchen remodeling on time, because fabricators avoid rework when the scope is precise.

Budgeting begins with realistic ranges that vary by region and complexity. Installed costs per square foot commonly fall near these bands:

– Laminate: about $20–$50

– Butcher block/solid wood: about $40–$100

– Solid surface: about $50–$110

– Engineered stone: about $60–$120

– Natural stone (granite, marble, soapstone): about $50–$150+

– Sintered stone/porcelain slab: about $70–$140

These figures rise with premium thicknesses, intricate edges, tight-radius corners, integrated drainboards, or extensive cutouts. Edge profiles may add a few dollars per linear foot; undermount sink cutouts and faucet holes typically have line-item charges; removal and disposal of old tops, plus temporary sink solutions, also affect the total.

Material selection blends aesthetics, durability, and upkeep. Engineered stone provides consistent color, strong stain resistance, and minimal maintenance. Many natural stones offer unique movement and depth but may require periodic sealing and careful heat management. Solid surface can deliver inconspicuous seams and integrated sinks; it is also repairable with sanding. Porcelain or sintered slabs excel at heat and UV resistance, with thinner profiles that still perform. Laminate remains cost-effective and attractive in modern patterns, though it is not intended for direct heat or heavy cutting. Wood brings warmth and can be resurfaced; it benefits from routine oiling in working zones.

Also consider lifestyle realities: heavy baking suggests a cooler surface near a pastry station; avid entertainers might prioritize stain resistance around beverage zones; families may value rounded edges and durable corners near high-traffic islands. A good plan aligns material strengths with how your household actually lives, so your new surface feels intuitive from day one.

Finding and Vetting a Countertop Contractor

Reliable fabrication and installation require more than a low bid. Start locally with showrooms and trade referrals, then verify credentials. Ask for proof of business registration, current liability and workers’ compensation insurance, and relevant trade licensure where required. A reputable shop will provide these without delay and welcome questions about shop equipment, templating methods, and in-house versus outsourced fabrication. This groundwork matters because kitchen remodeling succeeds when craftsmanship is paired with accountability.

Request recent, project-matched references and a portfolio that features:

– Similar materials and edge details to what you want

– Seam placements in comparable layouts

– Waterfall returns, overhangs, or complex cutouts if relevant

– Close-up photos that reveal polish quality and chip-free edges

If possible, visit a showroom to see slab samples in daylight and under varied angles. Run your hand along sample edges to feel micro-chipping or waviness, and look at seam mockups for color-matched adhesives and grain alignment.

Interview several contractors using a consistent script. Good questions include: What is your templating process, and who must be present? How do you determine seam placement and overhang support? What is the typical timeline from template to install? Which tasks are included in the bid (plumbing disconnect/reconnect, cooktop hookup, backsplash caulking)? How are natural fissures, resin fills, or shade variations handled? What happens if walls are out of square at install? Which warranties apply to labor and to the fabricated surface?

Finally, expect a written proposal that lists slab type and thickness, square footage, edge profile, number of cutouts, backsplashes, splash heights, seam locations (provisional until templating), disposal, protection measures, and the payment schedule. Clarify change orders and how unforeseen conditions are priced. Transparent documentation is a signature of a contractor who plans to deliver quality and stand behind the work.

From Template to Installation: Timeline, Quality Checks, and Safety

The path from measurement to finished countertop follows a sequence that rewards preparation. Templating captures your space precisely, using digital tools or rigid patterns to record walls that bow, appliance offsets, and cabinet reveals. Expect confirmation of edge profiles, overhangs, backsplash heights, and every cutout. Clear labeling of faucet hole spacing, air switch placement, and sink orientation prevents jobsite guessing. After template approval, fabrication typically takes 5–15 business days, depending on shop load, material availability, and complexity. Communicate any schedule constraints early; moving plumbing, electrical, or flooring can shift dates.

On installation day, the crew should protect floors, remove old tops if included, and dry-fit the first piece. Seams belong where they are least stressed and most discreet: away from cooktops when possible, centered under task lighting that minimizes glare lines, and aligned with pattern flow. Adhesives and color-matched seam compounds require careful mixing; clamps draw pieces together while the bond sets. Undermount sinks are set with mechanical fasteners and adhesive; avoid using them for 24 hours so the bond cures. If a penetrating sealer is part of the plan, allow proper ventilation and follow cure times before heavy use.

Homeowners can streamline the day with a few steps:

– Clear counters and base cabinets of stored items

– Remove fragile decor and create a path from entry to kitchen

– Confirm that plumbing and electrical are safely disconnected

– Keep children and pets out of the work zone

These courtesies help crews work efficiently and reduce accidents. Good teams leave minimal dust by using drop cloths and vacuums on hand tools, though some fine dust is normal and can be wiped down afterward.

Quality checks before sign-off include tight, level seams; consistent overhangs; stable support at seating areas; smooth, chip-free edges; and properly caulked splashes. Verify that faucet holes match the fixture you planned and that the sink reveal (negative, zero, or positive) matches the template notes. A brief punch list at the end protects both parties and ensures that the last 5 percent of details receive full attention.

Sustainability, Care, ROI, and a Final Checklist

Thoughtful material choices and care routines extend longevity and lower environmental impact. For sustainability, look for slabs with recycled content, locally quarried or manufactured options to reduce transport emissions, and responsibly sourced wood for butcher block. Reusing serviceable cabinets and improving layout rather than full gut demolition also reduces waste. Durable, low-maintenance surfaces can cut down on harsh cleaners and replacements over time, aligning beauty with stewardship and supporting long-term value in kitchen remodeling.

Care basics keep surfaces looking fresh:

– Use cutting boards; even hard stones can suffer from micro-abrasions

– Place trivets for hot pots and air fryers to avoid thermal shock

– Wipe spills promptly, especially oils, wine, and acidic foods

– Clean with a soft cloth and mild, pH-neutral soap; avoid harsh solvents

– Reseal natural stone every 1–3 years, or as water no longer beads

– Oil wood tops regularly and sand lightly to refresh working zones

Small chips at edges are repairable in many materials; ask your contractor about color-matched fillers and maintenance kits.

Return on investment depends on market and scope, but updated counters often boost perceived quality, help listings photograph well, and can shorten days on market. Many homeowners see meaningful value from a coordinated refresh that pairs new surfaces with lighting, hardware, and paint rather than a full structural overhaul. Neutral tones and timeless edges broaden appeal, while a single statement surface on an island can deliver personality without overwhelming the room. Durability is itself a financial strategy: sturdier edges, smart seam placement, and proven materials reduce service calls and future replacement cycles.

To wrap up, here is a quick hiring checklist you can save:

– Define scope, materials, edges, and every cutout in writing

– Collect two or three comparable bids with identical specifications

– Verify license, insurance, and recent, project-matched references

– Approve templates and seam plans before fabrication

– Reserve a quiet, protected jobsite and confirm utility shutoffs

– Inspect seams, overhangs, sink mounting, and splash caulking before sign-off

With a clear plan, a vetted pro, and realistic expectations, your new counters will look exceptional, perform day after day, and elevate the heart of your home.